Winch calculation

Get your sums right

At the basis of any equipment selection, winches or otherwise, is an assessment of what is required in terms of capacity and capability. To enable the correct selection of winch, motor and gearbox, it is essential that basic application parameters as Load and Speed are known and understood. Below a brief explanation is given about the data and calculations required for the primary winch selection. The essence of winching is to move objects from one position to another by means of a length of rope. The rope is fixed to the object at one end, and to the winch drum on the other.

The driving forces behind all this are called Power and Torque.

Force (required to move the load) is expressed in Newton (N), formerly (and even today) in kg (kilogram) or tonne. 1kg is officially 9.81 N, but for practical purposes we use 1 kg = 10 N.

Power is expressed in kilo Watts (kW). In the past and on the North American market power was expressed in horsepower which is about 0,7456998 kW.

Torque is expressed in Newton metres (Nm), formerly kilogram metres, and in some markets in foot pounds.

Physics

Power

As stated power is expressed in kW (kilowatt). In physics Watt can also be expressed in J/s (Joules/second). Joules can also be expressed in Nm (Newton metre), therefore Power can be expressed in Nm/sec.

This makes power more understandable, since we know the required Nm (line pull x effective drum radius) to move the load and the required speed at which the load has to be moved. The higher the speed (at a given load), the more power we need.

The calculations behind this look as follows: P(kW) = F(N) x V(metres/min) / 1020 x 60 In which P = power in kW, F = Force (line pull) in Newton, V = Line speed in metres/min, 1020 is a constant and 60 is a translation from minutes into seconds (Nm/sec).

Torque

With the required amount of power (kW) determined, the amount of torque (Nm) involved in the application must be determined. Depending on the effective drum radius and the load the torque at gearbox and motor level can be calculated. The amount of torque at gearbox level is important to make sure a sufficiently strong gearbox is chosen, and at motor level to make sure the load can be actually moved.

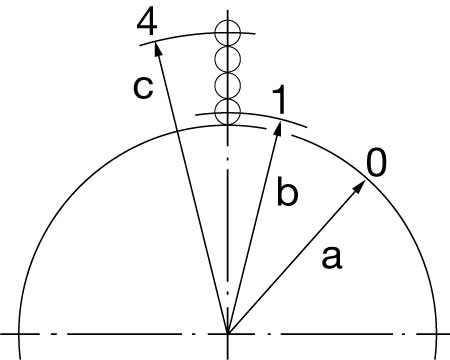

The effective drum radius used in this calculation is the distance between the centreline of the active rope layer and the centreline of the drum. For winches with only one layer of rope this is a constant factor. For winches with multiple layers the distance is a variable, and depends on the amount of rope wound on the drum. Please see Fig. 3-2 for the influence of the number of rope layers on the effective drum diameter.

a) Drum radius proper - b) Effective drum radius with one layer of rope - c) Effective drum radius with four layers of rope.

Note: The rope diameter (required for the above calculation) follows from the nominal winch load, the required safety factor and the type of rope selected.

Motor

The amount of torque and power resulting from the calculation must be translated into a motor type and size. Depending on what is locally available in terms of power supply or even available physical space, the motor emerging from the calculations may prove beyond what is possible. In that case the motor and winch performance have to be reduced to make sure the required power demand falls within the available power supply. Also make sure the motor can be physically installed onto the gearbox, and that effective motor power and torque (and in some cases motor speed) fall inside the operational limits of the gearbox. In case of doubt increase the gearbox dimension or configuration or reduce the winch performance.

Gearbox

Selecting the correct gearbox, the maximum torque value during operation (or with an applied brake) is leading. In case of doubt go up one size of gearbox, the possibly too generous extra torque capacity of the gearbox will translate into a longer life. Make sure the calculated gearbox can be installed into or onto the winch and that it matches with the selected motor and resulting motor performance.

Note: Gearbox dimensioning in relation the average operational load of the winch is one of the most important factors.

Drum dimensions

The winches found in the EMCÉ catalogue have drum diameters and lengths that have proven themselves during many years of real world use, and will be perfect for most standard applications. When special demands or requirements are present, it may be required to calculate with a non- standard drum. A few rules must be respected calculating a non-standard drum which are outlined below.

Diameter

The minimum drum diameter follows from the minimum rope bending radius. Drum diameter/rope diameter ratio should not be too small since rapid rope wear will result, and for this reason the rope/drum ratio is stipulated in many regulations. The drum however may have a (much) larger diameter to enable storage of the required length of rope within a given drum width and number of rope layers. A larger diameter drum stores more rope for a given width, but also increases the effective drum radius and therewith the required torque for a given load. Make sure the diameter used in the calculation is an "existing" diameter i.e. a diameter that is available in the EMCÉ catalogue for (bigger) winches of the same model. Alternative dimensions can be specified, but will increase the cost of the modification unnecessary.

Note: Also make sure the drum flanges have a sufficiently large diameter to comply with the regulations. Depending on the regulation applicable the upper rope layer must remain 3-5 rope diameters below the edge of the flange. As with drum diameters it is advisable to use "existing" flange diameters. Again make sure an "existing" diameter is selected for the flanges, the same logic as for the drum diameter applies.

Width

Drum width can be more or less chosen freely to suit the application, but increasing the drum width has a negative effect on the fleet angle of the winch rope, while at the same time winch footprint and winch cost increase. The EMCÉ standard drum dimensions as shown in the catalogue provide a sensible balance between rope storage, winch performance and winch dimensions.

Note: Make sure the drum width is sufficiently large to store at least an extra three safety wraps for steel wire rope and at least 6 safety wraps for man-made fibre ropes that will remain on the drum under all circumstances for safety reasons.

Frame dimensions

Frame dimensions usually result from the drum length and the combined length of transmission and motor. These dimensions can be derived from the catalogue information, and when a longer than standard drum is specified, the extra length can simply be added to the catalogue figures. Special care is required when bigger (longer) motors or gearboxes than standard are specified, or when extra equipment like clutches or band brakes are added to winches. Please contact the EMCÉ sales department for the effect this extra equipment will have on the frame dimensions. Make sure that the available space for installing the winch is sufficient for installing the winch itself and for the extra space required needed to operate and maintain the winch.

Calculating the power supply

For any power driven winch or capstan a form of power supply needs to be available on the installation site. The standard power demand, be it in Volts and kW or pressure and volume can be taken from the catalogue or from your own calculations as shown above. Make sure the available power on site is at least slightly in excess of the nominal required power demand to allow for sligth voltage and pressure drops or a occasional peak demand from the equipment. In case of doubt contact the EMCÉ sales office for information regarding the power supply to be installed.