Winch type MR30FLH

| Product code | EMMR30FLH |

|---|---|

| Manufacturer code | MR30FLH |

| Medium | Hydraulic |

| Application | Pulling |

| Series | MR FL-series |

| Working Load Limit (WLL) [kg] | 200 kg |

| medium | Hydraulic |

|---|---|

| environment | Oil and Gas |

| application | Pulling |

| series | MR FL-series |

| working Load Limit (WLL) [kg] | 200 kg |

| number of layers | 5 |

| lifting WLL first layer | 200 kg |

| lifting WLL top layer | 150 kg |

| speed top layer | 43 m/min |

| drum capacity top layer | 125 m |

| rope diameter | 10 mm |

| flow | 25 L/sec |

| pressure drop | 70 bar |

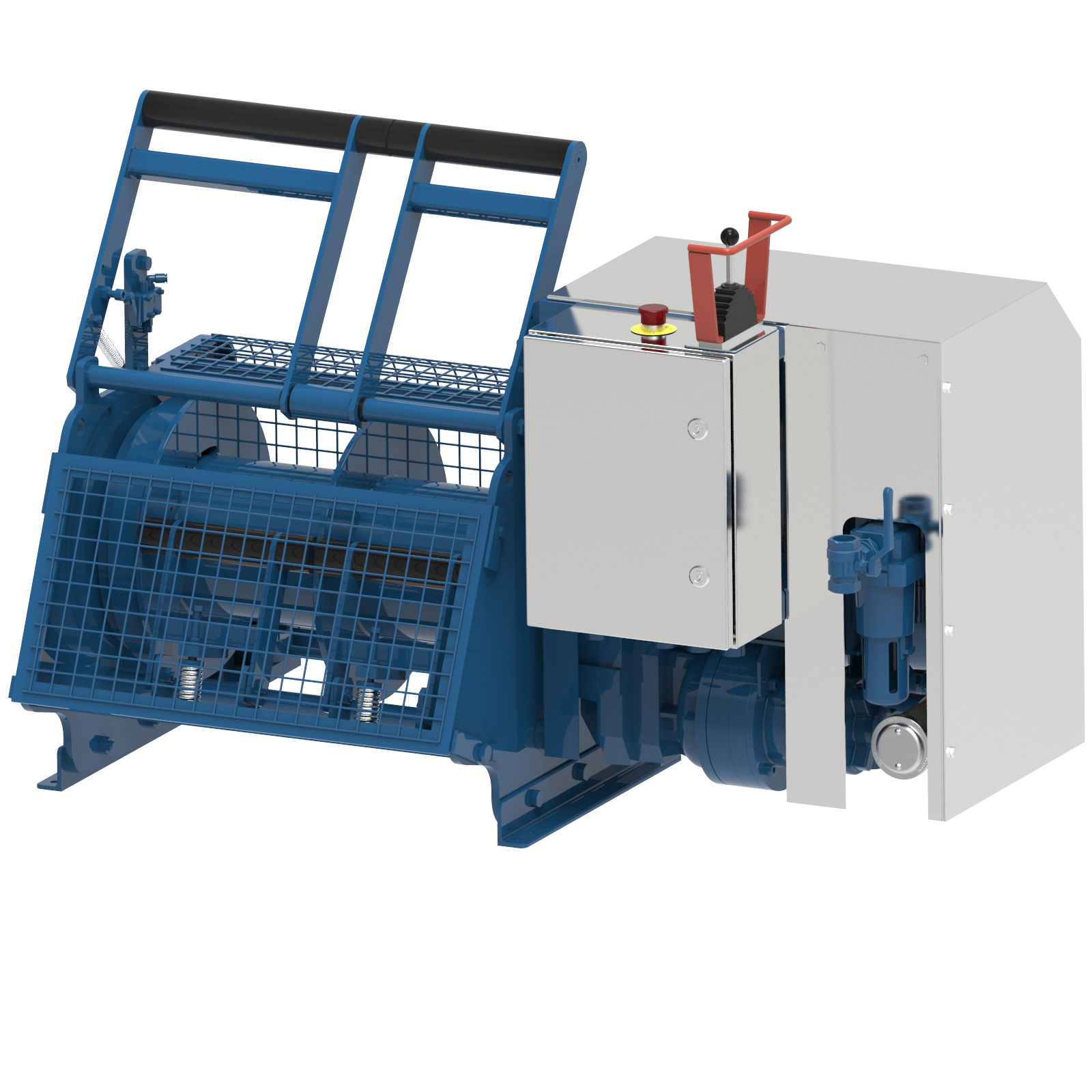

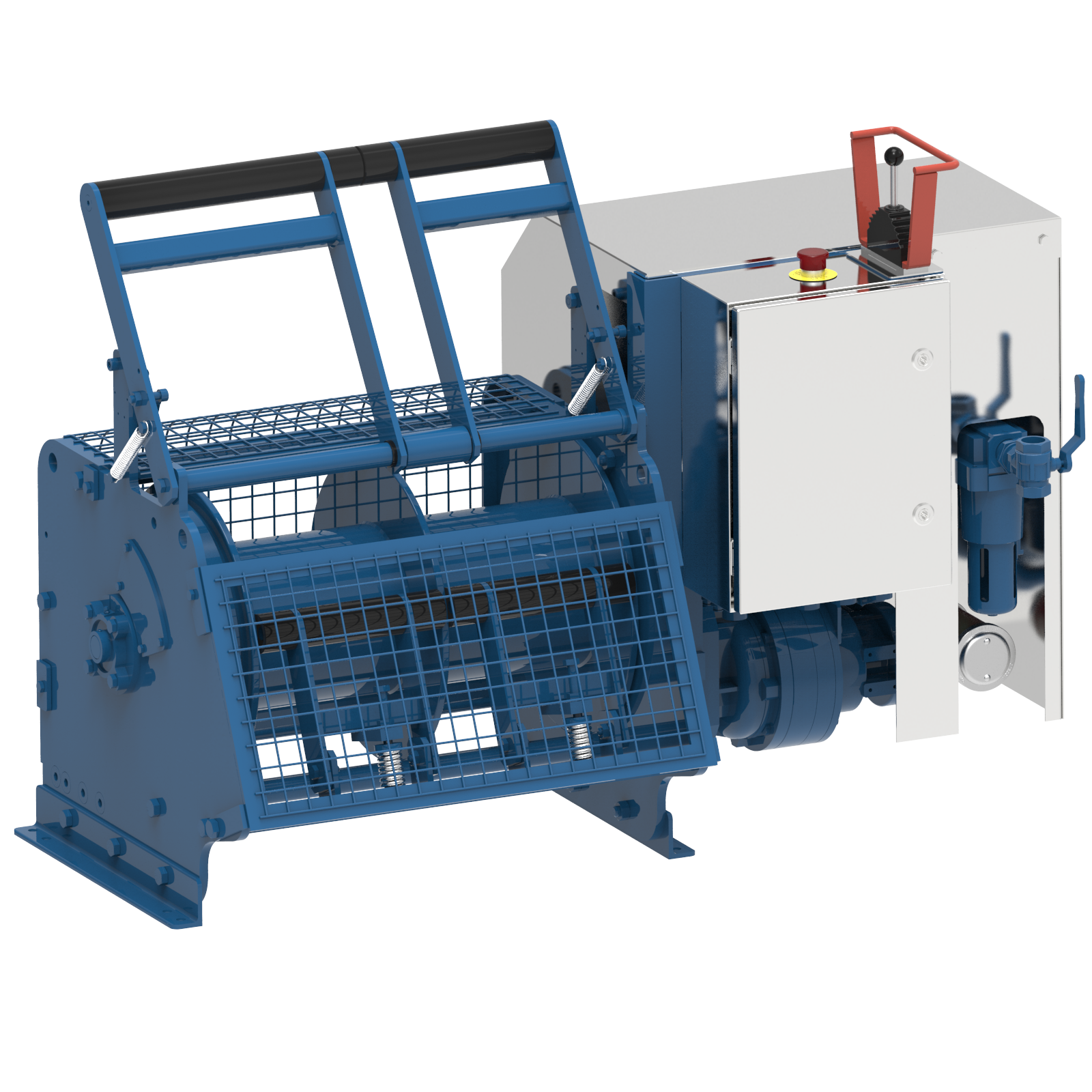

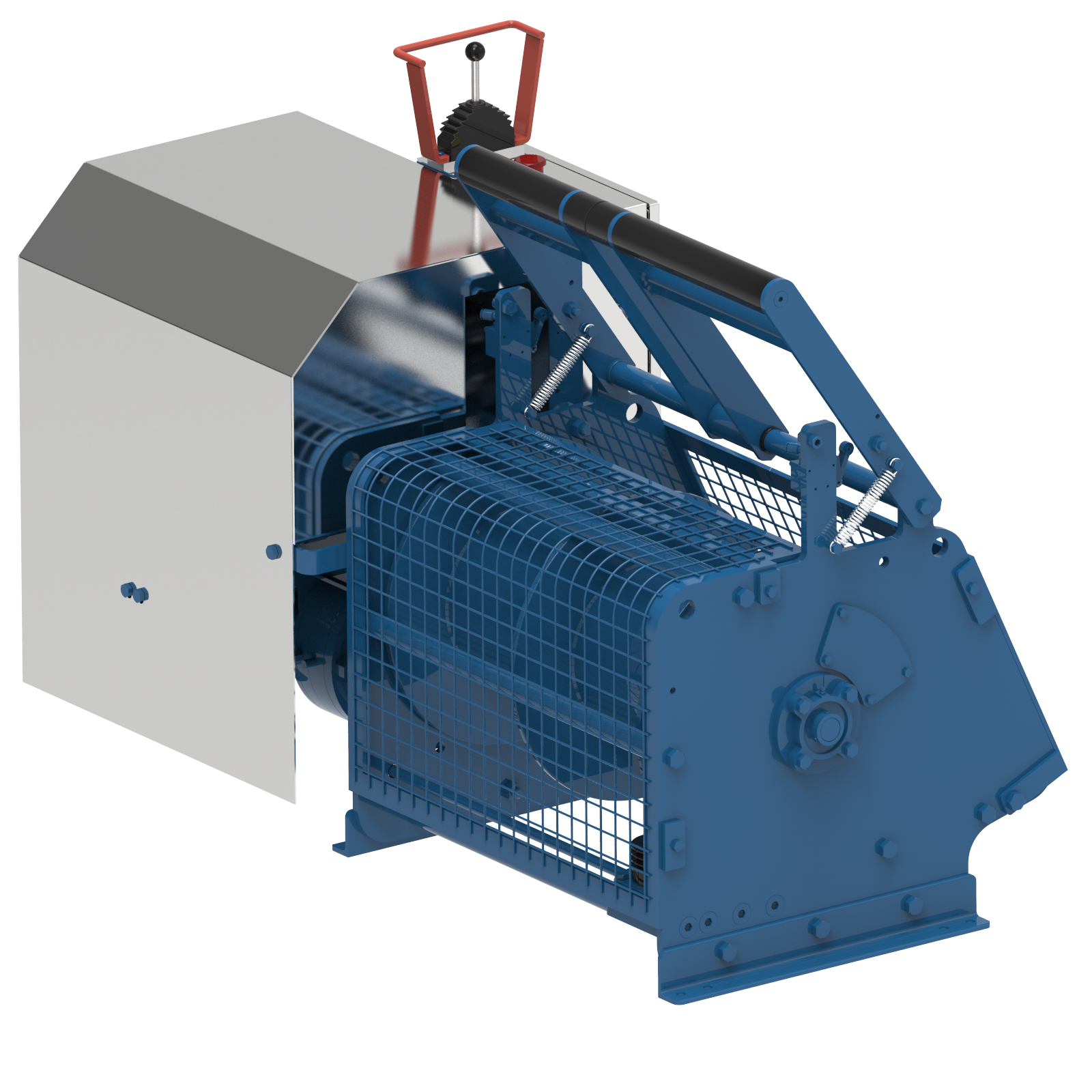

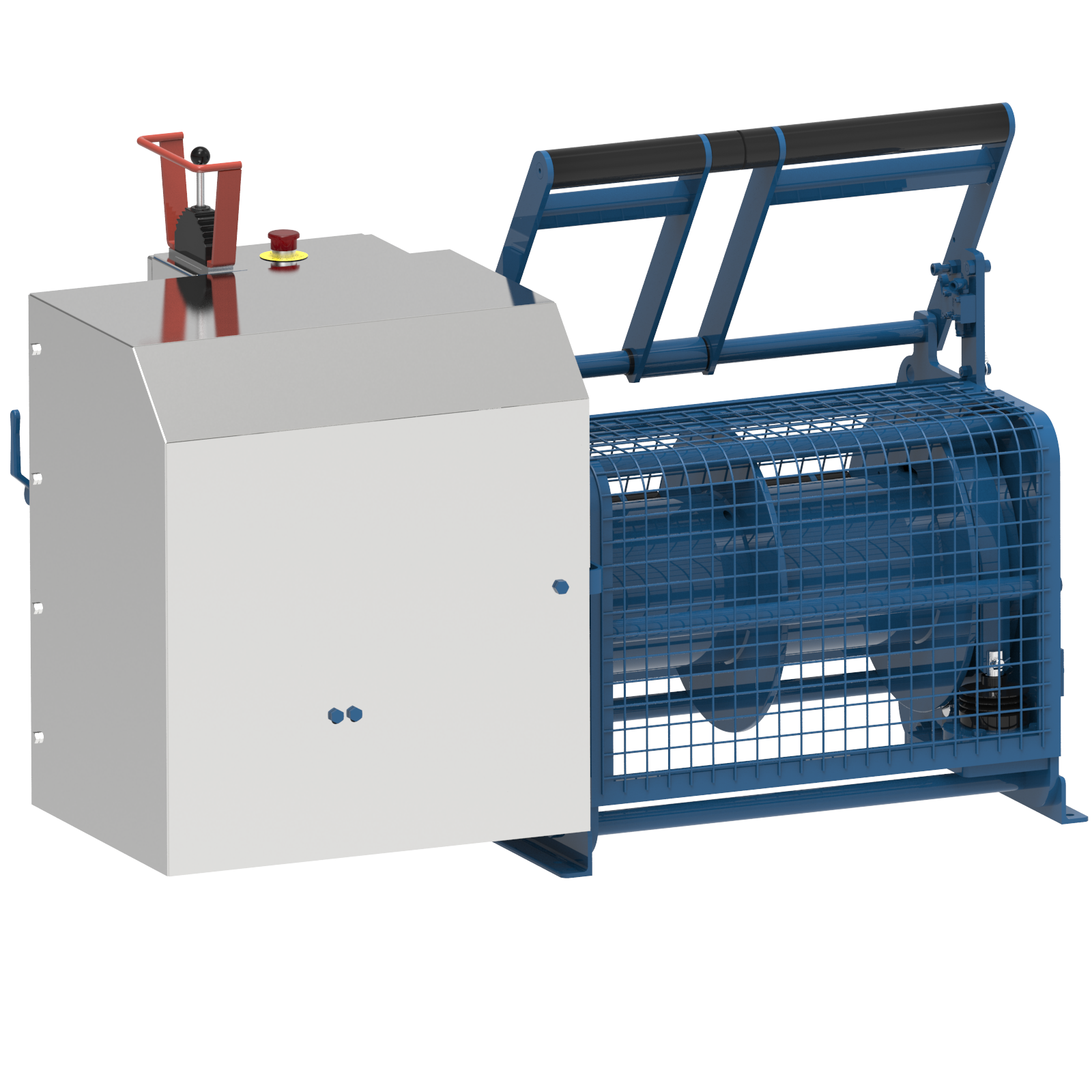

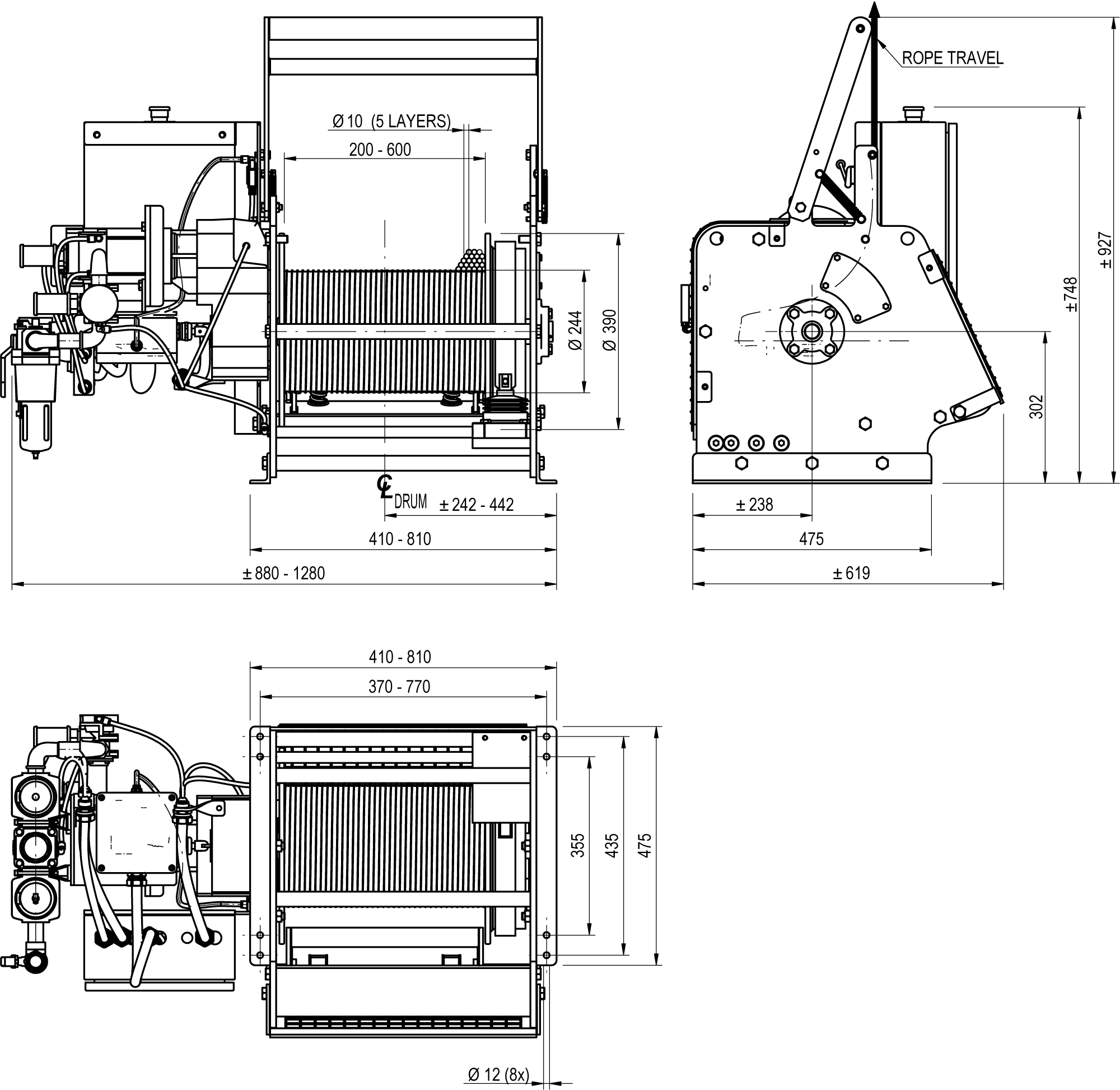

Drawing

Designed to the standards issued by the classifi cation bodies and it meets the UK HSE regulations for personnel lifting operations on offshore installations. The winches are dedicated personnel lifting winches supplied with full material traceability. They have passed EC testing for these applications, i.e., both the winches and their technical fi les are in compliance with the requirements of the EC Machinery Directives.

The MR 30 FL winches have been specially designed for personnel lifting applications in which a safety harness or a boatswain´s chair is used on fi xed installations with a total WLL of 150 kg. The MR 30 FGL winches have passed EC testing for these applications, i.e., both the winches can be supplied with a Lloyds Register of Shipping (LRS), ABS or DNV Design Appraisal Certifi cate.

The MR 50 FL and MR 60 FL have been designed for use with assemblies using a platform, basket, carrier, etc, with a total WLL of 500 kg for the MR 50 FL and 1000 kg for the MR 60 FL.

Standard features

- Helical shaft mounted gearbox, life lubricated with synthetic oil

- UK HSE compliance

- Caliper primary brake 180% of WLL

- Automatic band brake as secondary drum acting brake 180% of WLL

- Pneumatic gearmotor

- Obit hydraulic motor

- Helical grooved steel drum

- Full material traceability (3.1 - EN 10204) on load-bearing parts

- Two drum supports

- Limit switch

- Slack wire switch

- Overload protection device

- Local proportional control with biased control valve (pneumatic models only)

- Local proportional control with biased control valve (MR 30 FLP/FLV only)

- Drum guard

- Muffl ers (on MR 30), 50 en 60 FLG

- Prepared for emergency lowering system

- Air service unit (pneumatic models only)

- Main air emergency stop valve

- Operating conditions –20°C to 50°C

- Three layer 2-component conservation according ISO 12944 category C4-High, colour RAL 1023

- FEM / ISO class: T4-L3-M5

Mechanical options

- Electric versions

- Alternative speeds

- Alternative drum dimensions

- Air service unit

- Pre-equipped emergency lowering device including nitrogen air receiver (MR 30 FLG only)

- Design appraisal certifi cate from LRS, ABS or LRS

- Including certifying authority witness test

Control options

- Electric/hydraulic or pneumatic control systems

- Pneumatic pendant remote control on portable pedestal

- Pneumatic pendant remote control with shoulder harness