|

medium |

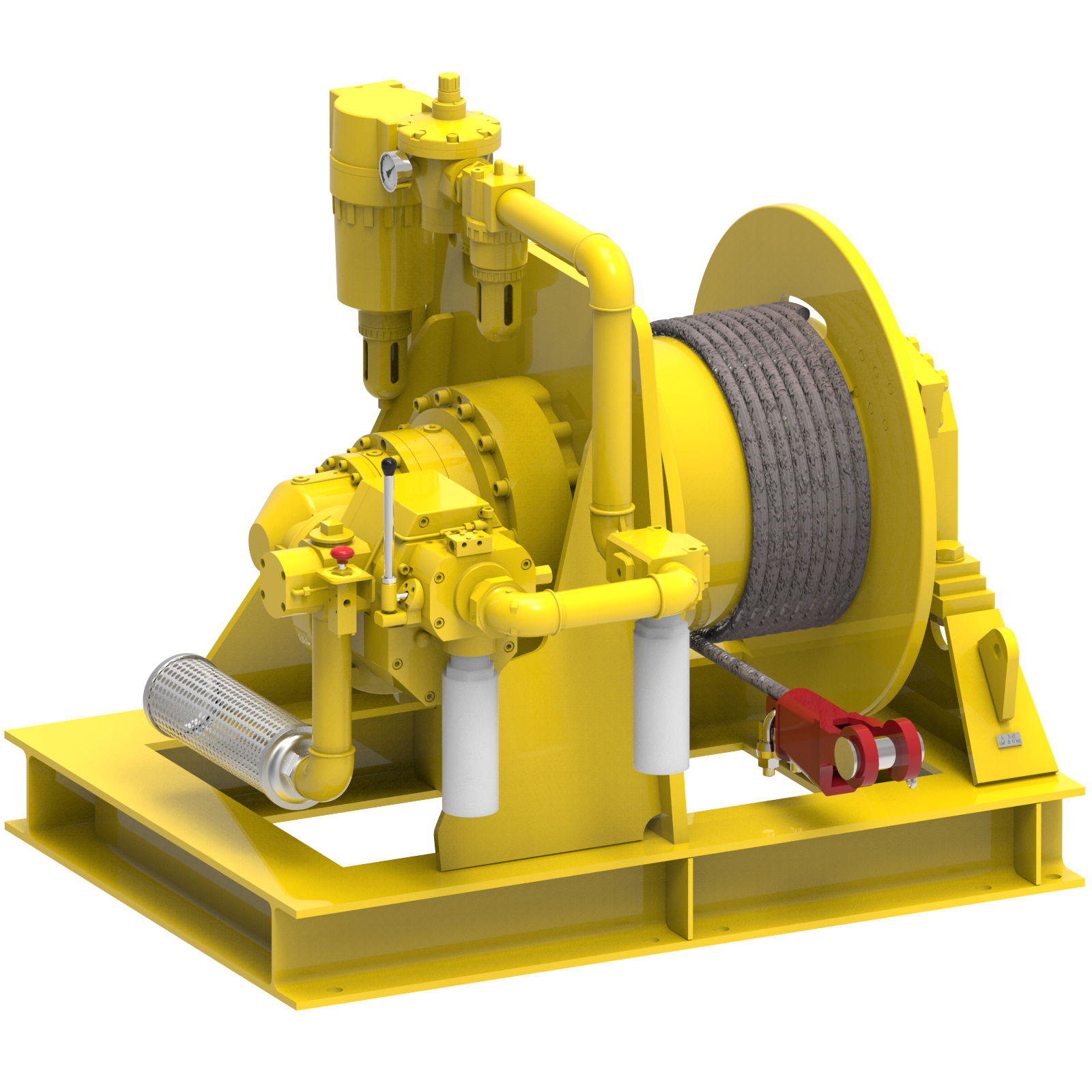

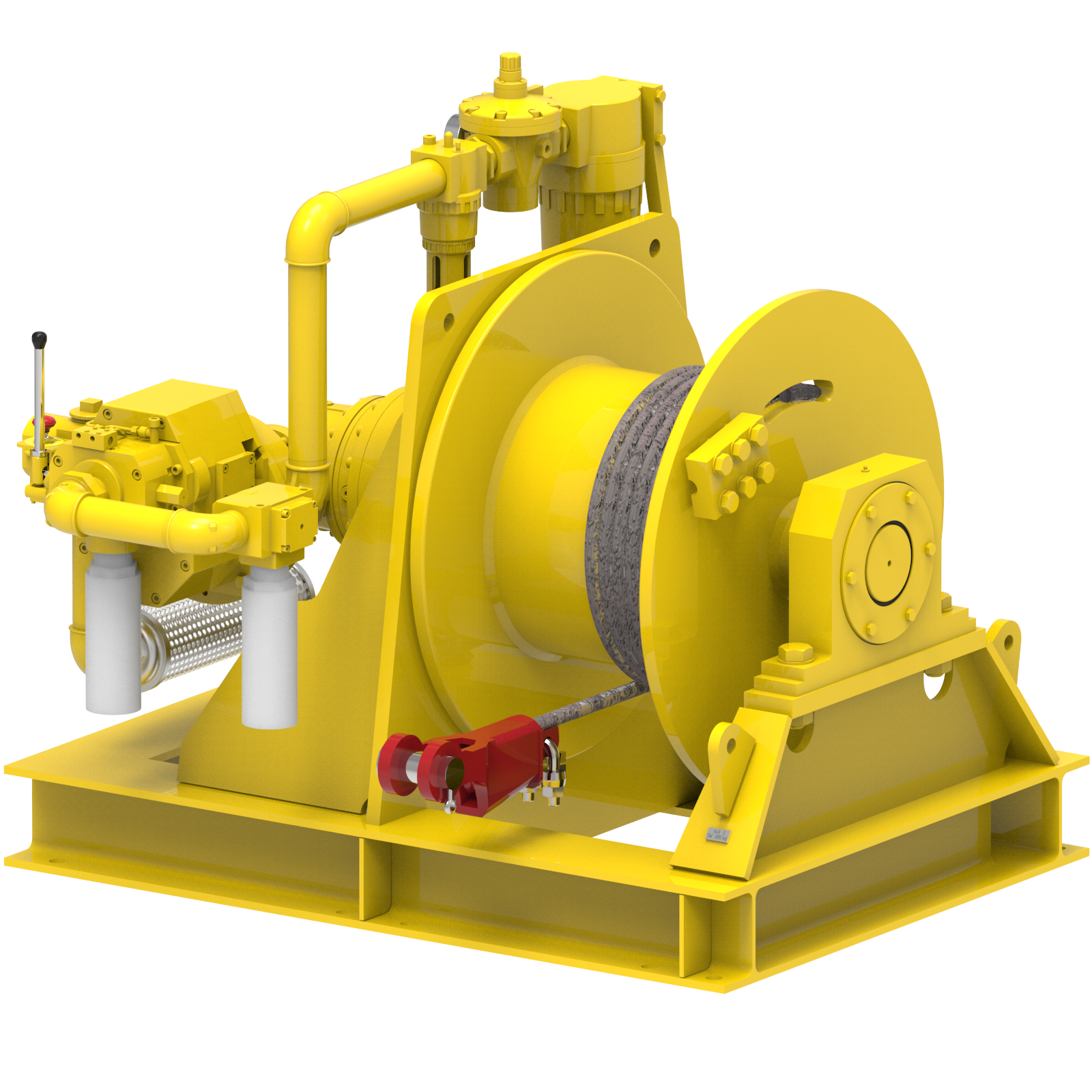

Pneumatic |

|

environment |

Oil and Gas |

|

application |

Traversing |

|

series |

SB-series |

|

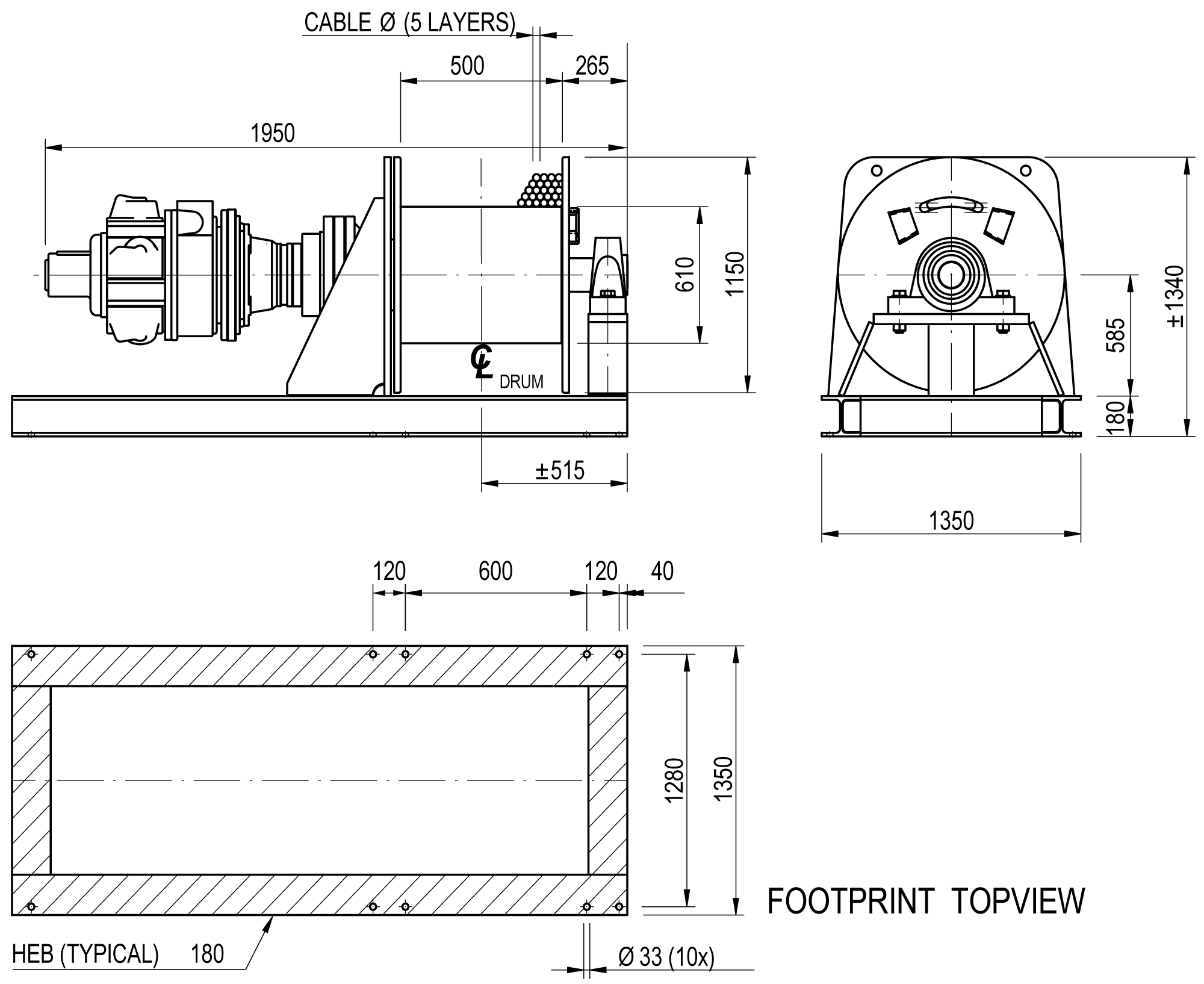

working Load Limit (WLL) [kg] |

20000 kg |

|

number of layers |

5 |

|

lifting WLL first layer |

20000 kg |

|

lifting WLL top layer |

13610 kg |

|

speed at first layer |

5 m/min |

|

speed top layer |

12 m/min |

|

drum capacity first layer |

19 m |

|

drum capacity top layer |

151 m |

|

rope diameter |

38 mm |

|

mass |

2270 kg |

|

flow |

350 L/sec |

|

pressure drop |

7 bar |

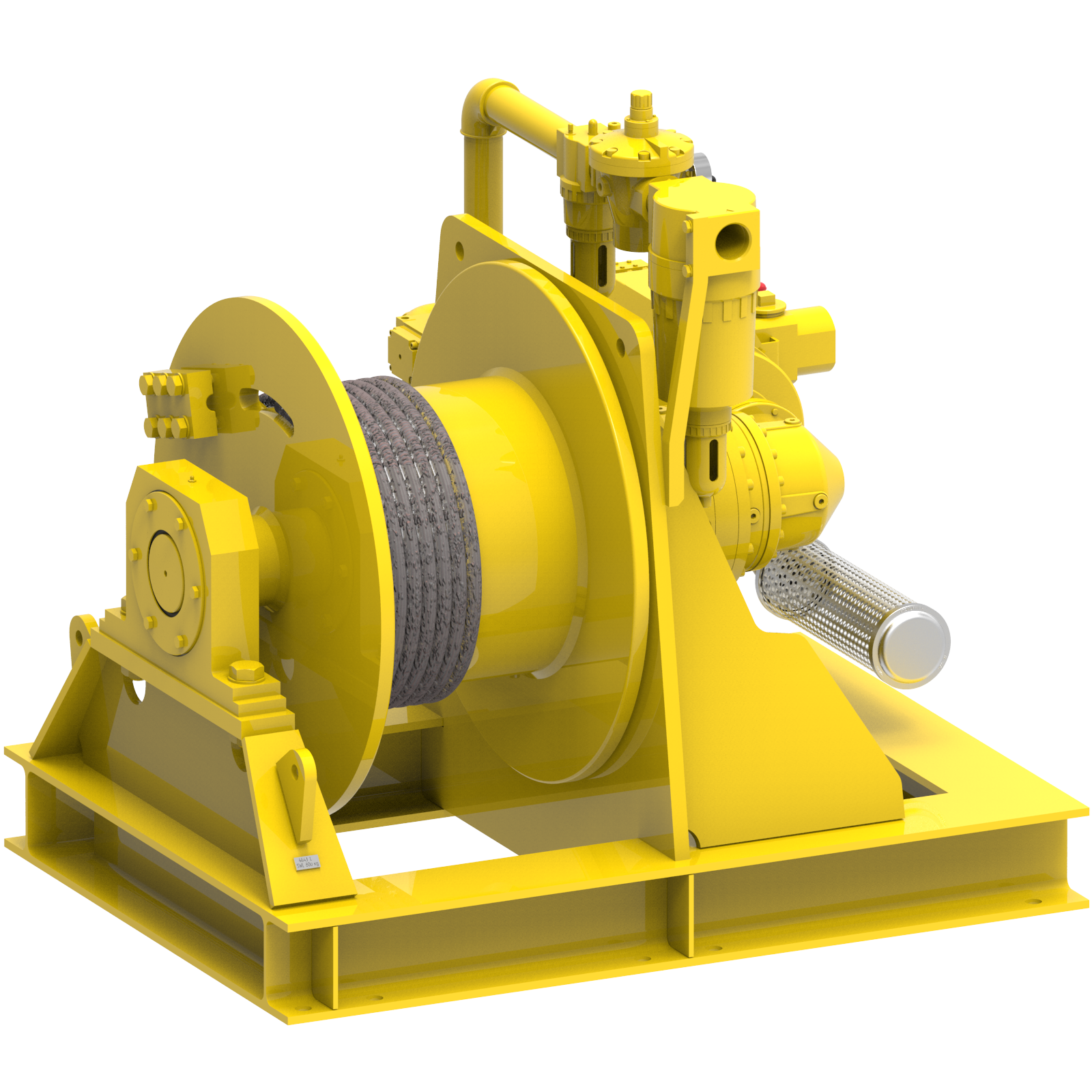

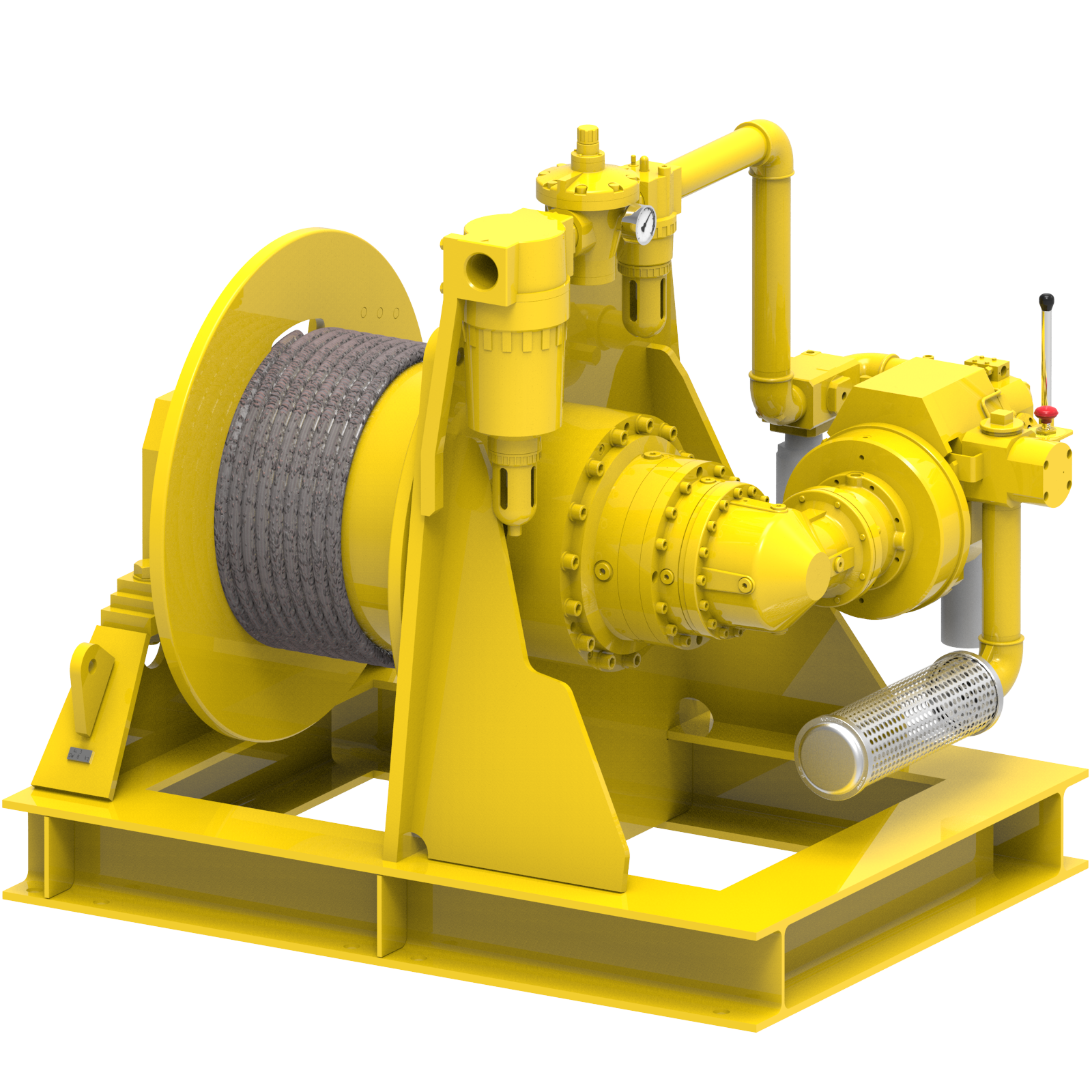

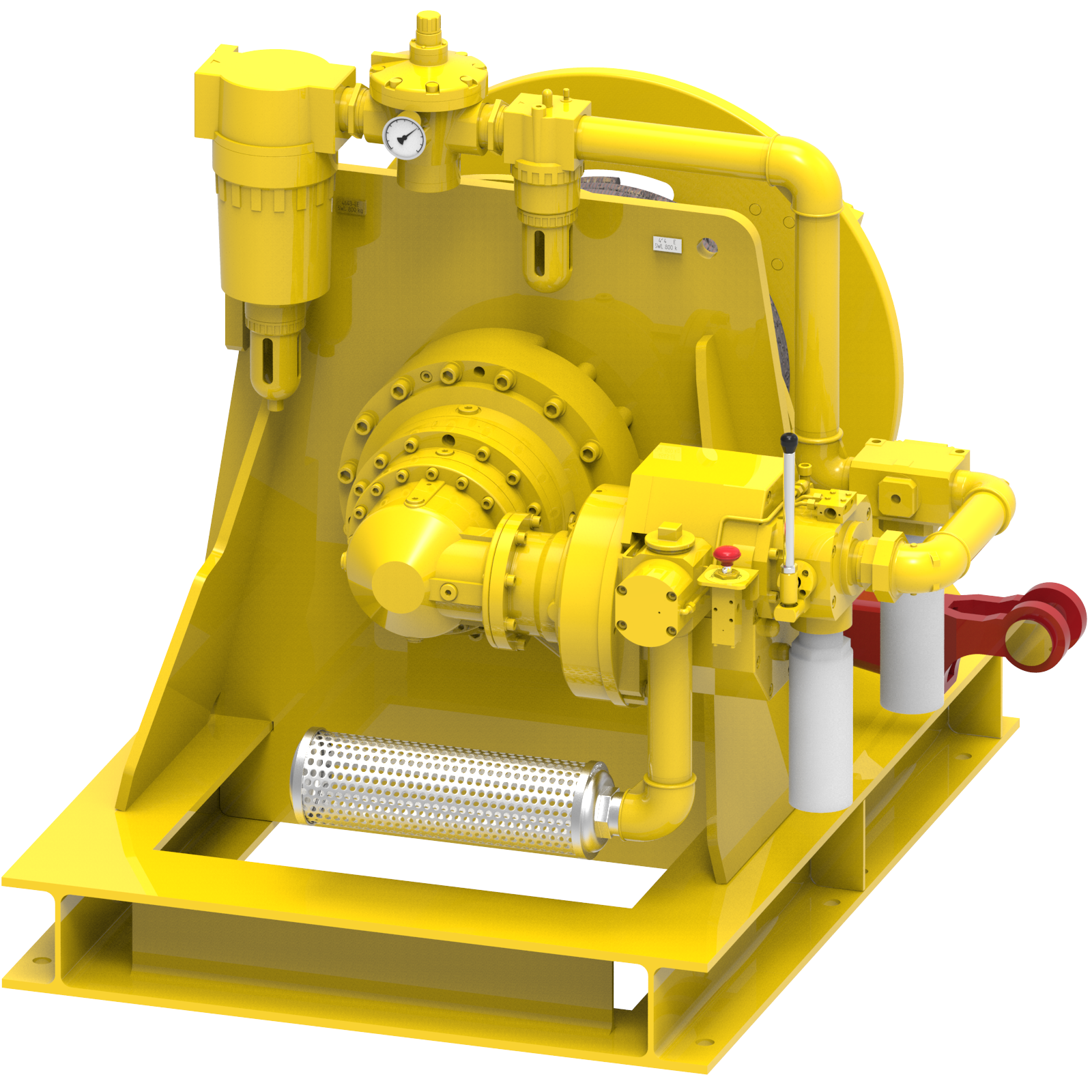

The abbreviation SB stands for Standard Build, but a standard SB does not exist! Possibly more than any other EMCE winch the SB series can be adapted to suit almost any role the customer has in mind for it. Pulling, lifting or hose- and cable reel tasks it takes it all in its stride. Thanks to its simple construction with all key components readily visible and accessible, the basic design can be scaled up or down to enable the SB series to cover a load range from a few hundred daN to 70 tons. Due to their accessible location, dimensions of key components as bearings, gearboxes and motors can be selected as per requirement, without altering the core design. While gearbox dimensioning, capacity or even make can be selected depending on the task to performed, this gearbox will always be of the planetary type. The planetary gearbox system offers many advantages. Compact, reliable, infinitely variable gear ratios and an unsurpassable variation if in and output variations makes this the ideal gearbox for an almost ideal winch. Thanks to this in- and output side adaptability, a wide variation of motors, brakes or even auxiliary step-down gearboxes can be mounted. The wide variation in motors covers different types and sizes of electric, hydraulic and pneumatic motors, enabling an accurate and efficient selection of power plant. To cater for the different dimensions of power plant, the winch frame, due to its extreme simplicity, can be extended or shortened as required. Another feature of the frame simplicity is the ease at which auxiliary equipment as band brakes, clutches, pressure rollers or spooling gears can be attached to or integrated into the frame. Also the frame is the sturdy base for mounting protective cages to protect the winch in more demanding environments. The protective case can be just a number of sturdy beams and a protective roof, but can also be fitted with paneling to seal of the winch from the environment, or prevent tempering with the winch in unsupervised locations. Needless to say that a control panel, when fitted, is usually fitted to the frame, and will be located inside any protective frames or enclosures.

What can be found as standard on all SB winches?

- A sturdy mild steel beam frame with integrated gearbox bulkhead and bearing support

- A heavy duty planetary gearbox

- A mild steel drum with welded on side flanges

- Cable clamp or socket on the drum flange to suit the application

- Double layer 2 component paint system C2 low acc. to ISO 12944 in RAL 5010 Blue

-

- On electric winches: Electric motor with integral brake with brake rectifier (where applicable)

- On Hydraulic winches: Orbit or radial piston motor with hydraulically operated transmission brake with brake valve

- On Pneumatic winches: Gear or radial piston motors with pneumatically operated transmission brake with winch control valve and muffler.

(On pneumatic winches the indicated first layer speed is an average speed, while top layer speed is the no load maximum value)

- Certificate documenting the thorough functional and operational load test

- Full compliance with the EC machine directive

What can be ordered as extra on SB winches?

Mechanical options

- Protective covers over motor and/or gearbox

- Drum guards

- Pressure roller

- Band brakes (automatic or manual)

- Manal clutch to disconnect the drum form the drive

- Spooling gears (mechanically or electrically driven)

- Alternative drum diameters and lengths

- Grooved drum (Spiral or Lebus®)

- Split drum executions

- Slip ring or Swivel installation (for hose or cable reel use)

- Warping head (usually in combination with band brake and clutch)

- Emergency backup drive system (manual , electric, pneumatic)

Control options

- Control boxes for electrical winches, from simple push button to advanced inverter type

- Proportional control systems for hydraulic and pneumatic winches

- Load limiter (compulsory in EC for lifting over 1000 daN)

- Constant tensioning control systems

- Radio remote control systems (available for electric, hydraulic and pneumatic winches)

- Upper and lower limit switches

- Slack rope detection system

- Extended emergency stop provisions

- Visible and audible warning and communication provisions

- Cable length and or load monitoring systems

- Alternative motor and control voltages

Environmental options

- Increased IP rating on electrical motors and equipment (up to IP 67)

- ATEX or IECEx compliant executions

- Increased protection paint systems for Marine and offshore applications

- Versions for very low or very high ambient temperatures

- Food quality or Bio degradable lubrication options

Certification options

- CE declaration of Incorporation or Conformity

- Witness test for all major Classification Bureaus

- Designs in accordance with the design rules of all major Classification Bureaus

Support options

- Extended documentation package (recommended for all not fully standard winches)

- Commission and operator training on site

- Staff training on site or at the factory

- Spare part packages tailored for intended use and autonomy

- Repair and maintenance support